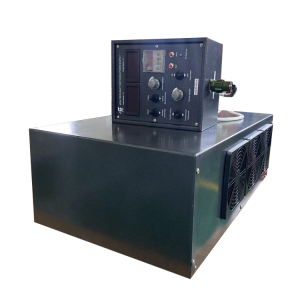

Polarity Reverse DC Power Supply Plating Rectifier 20V 500A

feature

-

Input Parameters

AC Input 380v±10% Three Phase -

Output Parameters

DC 0~20V 0~500A continuously adjustable -

Output Power

10KW -

Cooling Method

Forced air cooling -

PLC Analog

0-10V/ 4-20mA/ 0-5V -

Interface

CE ISO9001 -

Control Mode

Remote control -

Screen Display

Touch screen display/ digital display -

Multiple Protections

OVP, OCP, OTP, SCP protections -

Warranty

1 year

Model & Data

|

Model number |

Output ripple |

Current display precision |

Volt display precision |

CC/CV Precision |

Ramp-up and ramp-down |

Over-shoot |

| GKDH20±500CVC | VPP≤0.5% | ≤10mA | ≤10mV | ≤10mA/10mV | 0~99S | No |

Product Applications

Polarity reverse dc power supply deployed in large scale wastewater treatment plants.

Electrocoagulation and Electrooxidation

Wastewater treatment plants often employ electrochemical processes such as electrocoagulation and electrooxidation to remove contaminants. These processes involve the use of electrodes that generate coagulants or facilitate oxidation reactions.

Metal Recovery: In some wastewater streams, valuable metals may be present as contaminants. Electrowinning or electrodeposition processes can be employed to recover these metals. A polarity-reverse power supply can be beneficial in optimizing the deposition of metals onto electrodes and preventing the buildup of deposits that could hinder the process.

Electrolysis for Disinfection: Electrolysis can be used for disinfection purposes in wastewater treatment. Reversing the polarity periodically can help prevent scaling or fouling on the electrodes, maintaining the effectiveness of the disinfection process.

pH Adjustment: In certain electrochemical processes, pH adjustment is crucial. Reversing the polarity can influence the pH of the solution, aiding in processes where pH control is necessary for optimal treatment.

Preventing Electrode Polarization: Electrode polarization is a phenomenon where the efficiency of electrochemical processes decreases over time due to the accumulation of reaction products on the electrodes. Reversing the polarity can help minimize this effect, ensuring consistent performance.

contact us

(You can also Log in and fill in automatically.)